Taking the scientist out of science

Measuring can have its consequences.

You can’t always take a sample to the lab.

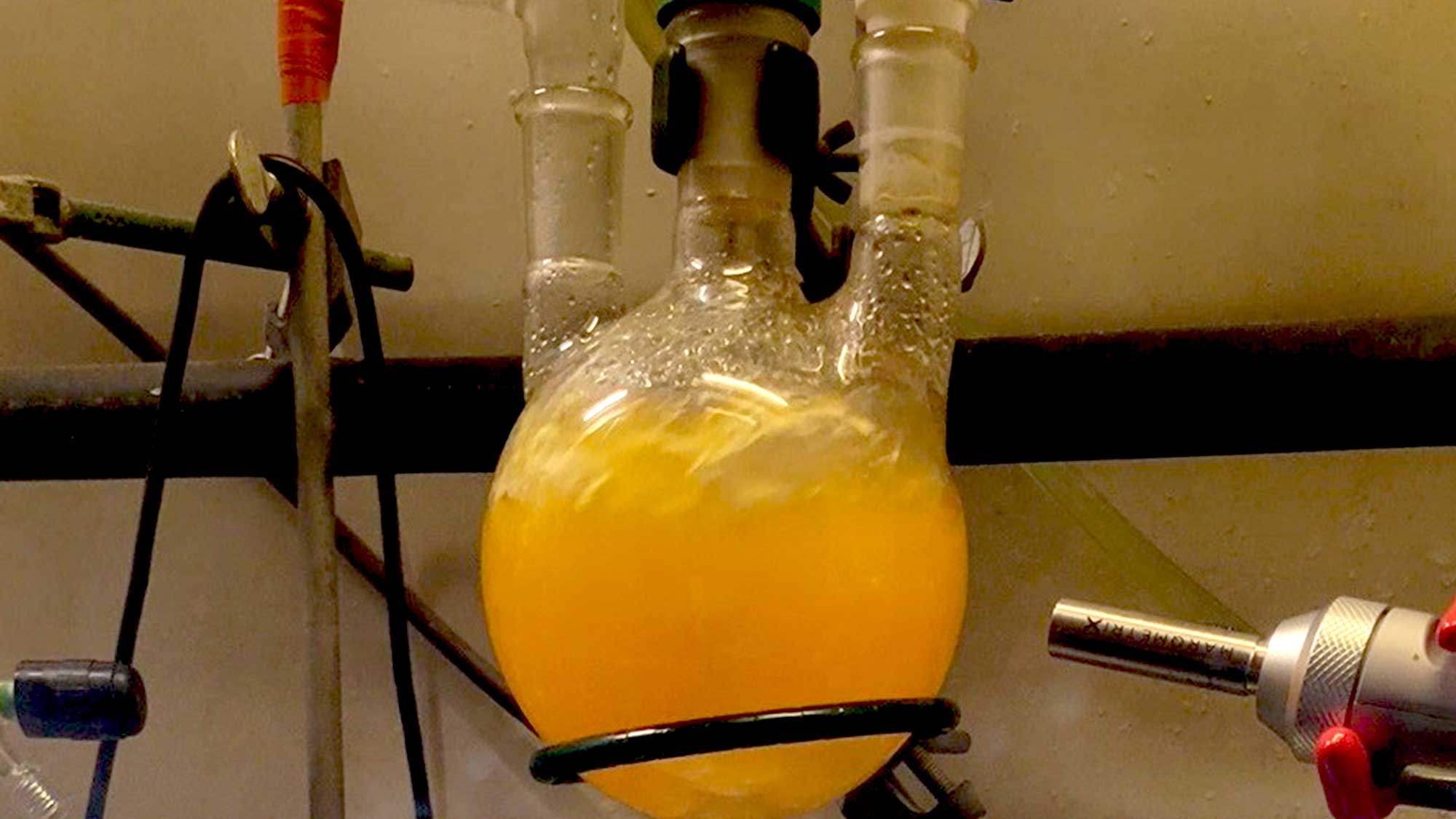

For example, if you try to take a sample of a pyrophoric material and it comes into contact with air, the whole thing will catch alight and start a fire.

The solution is to use a probe and take the measurements directly for real-time compositional analysis.

MarqMetrix developed Raman technology, which uses light and vibration to measure the chemical composition of a sample. Founded in Seattle in 2012, MarqMetrix, Inc. was established by Brian Marquardt and Scott Van Vuren and was recently acquired by Thermo Fisher Scientific.

“At the time, Raman had been a fairly esoteric technique that required finicky gear and a scientist—typically a PhD—to manage it. We took a page out of the personal computer playbook and sought easy access for anyone,” says Scott Van Vuren, Co-Founder and Chief Commercial Officer. “We can teach an inexperienced user to take a Raman sample literally within 15 minutes of receipt of the boxes. That’s unheard of in analytical instrumentation.”

We can teach an inexperienced user to take a Raman sample literally within 15 minutes of receipt of the boxes. That’s unheard of in analytical instrumentation.

—Scott Van Vuren, Co-Founder and Chief Commercial Officer, MarqMetrix, part of Thermo Fisher Scientific

“It’s powerful. It’s immediate. I’m actually measuring the sample, not making inferences about the sample’s properties,” says Van Vuren. “For example, I’m not looking at a color and saying, because this is pinkish blue, the sample must be the following. I’m literally taking a molecular fingerprint of the sample.”

The goal is to make deploying Raman spectroscopy as easy as using a thermometer. “We’re pursuing the notion of taking sampling out of the lab and getting it into the field to drive safety, to drive sustainability,” says John Richmond, Senior Manager Sales, MarqMetrix. “The more immediate, non-invasive measurements we can take will provide any production ecosystem with more information to make better products—from food safety to fuel safety.”

“The Raman system includes everything needed to monitor a process, including core models that help testers get answers quickly and easily,” says Richmond. “MarqMetrix invested considerable time and effort into core models. Gasoline manufacturers need to measure octane; there is a model for that. If we didn’t provide our customers with models, it could take them 6 to 12 months and several hundred thousands of dollars to build those models themselves. We offer the models out of the box, to get customers up and running.”

“The device is very consistent,” says Van Vuren. “It’s factory calibrated and doesn’t require end-user intervention on a daily, weekly, or monthly basis. We’ve been running a factory calibration study for almost five years now, and there’s no deviation in the signal that we receive every Monday morning. This is unheard of in the analytical instrumentation business.”

MarqMetrix is working with new sectors driven by sustainability including hydrogen and battery recycling. They are also heavily involved with natural gas power generation facilities that want to reduce their carbon footprint by reducing the carbon amount being used in the natural gas, so they blend hydrogen into the power generators.

“You have to know exactly how much hydrogen you are putting into the blend to enable the generators to still operate efficiently. If you have too much hydrogen, it’s not going to work well,” says Richard. “The ignition’s not going to be good; the efficiency’s not going to be good. If you don’t have enough, then you are using up too much carbon. So real-time analysis and relevant spectroscopy is another way that we are working for a sustainable future.”

Raman spectroscopy is also helpful in the manufacture of sustainable aviation fuel. The U.S. government and other governments around the world are seeking blends and sometimes forms of 100% sustainable aviation fuel (SAF). MarqMetrix helps a number of major manufacturers of SAF, making their processes more efficient, increasing their yield, and making sure that quality of the product coming out matches critical benchmarks.

John Richmond will present a seminar, “Rapid Compositional Analysis of Gas Phase Streams Using a Process Raman Analyzer.” In the gas phase realm, there is a growing need for rapid composition analysis near the wellhead in exploration gas scenarios. This analysis, typically conducted within seconds, aims to assess methane to hexanes alongside nitrogen and carbon dioxide levels. Gas chromatography stands out as the incumbent technology for this purpose, offering an alternative to the competitive technology currently employed.

“Raman spectroscopy is faster and it gives the analysis in seconds. Plus, there are no consumables, no car gas, no maintenance,” says Richmond. “You’re getting proper results at a much lower cost. This is a big issue with gas chromatography. The carrier gas is typically helium, and there’s a helium shortage. The cost of owning a GC is going up every year.”

John Richmond and Tom Dearing, Senior Staff Scientist, Research & Development, MarqMetrix, will co-present “Determination of Acid Value Using Raman Spectroscopy and Chemometric.”

Raman spectroscopy presents a non-destructive and efficient method for analyzing the composition and physical properties of various materials, including polyester resins and alkyd resin. This study specifically explores its application in quantifying acid value, a crucial factor in assessing acidity and viscosity, both vital aspects of fluid dynamics. The approach involves obtaining Raman spectroscopy from different chemical samples and utilizing multivariate analysis techniques to establish reliable calibration models for predicting acid value and viscosity. The findings underscore the effectiveness and accuracy of raman spectroscopy in providing real-time measurements, which positions it as a valuable tool for routine analytical processes across industries like petrochemicals, pharmaceuticals, and food processing.

Attendees will learn how Raman spectroscopy can provide molecular vibrational information, enabling non-destructive and rapid characterization of the composition and physical properties of polyester resins, alkyd resins, and other chemical materials.

Attendees are invited to come to the booth to touch, feel and see the complete Raman system, including the spectrometer sampling accessories. “If they need to know how to do gas phase analysis, we’ll have that sampling there. If they need to measure liquids and slurries or solids, we’ll have those there. If they need to measure in a non-contact way over a conveyor belt and they’re not allowed to touch the sample, we’ll have those accessory sampling accessories there,” says Richmond. “The sampling area is going to be huge and people are going to learn a lot about how they can measure their own particular types of samples.”

In the next few years, the spectroscopy technology will be combined with artificial intelligence, which will allow companies to work faster and more efficiently. The technology will also quickly evolve to be smarter with AI, with devices becoming smaller and costing less.