Intelligent Opps for the Modern Corporation

You can see operational excellence in action.

“Our customers are running the plant, our customers are flying aircraft, and our customers are operating the building,” says Ravi Srinivasan, VP GM Industrial Innovation.

Honeywell is dedicated to helping customers run their plants more efficiently and effectively at the lowest cost of operation. They also help improve asset performance, increase uptime, and keep plants and assets secure. “This has been the core theme of Honeywell for all these years, and every investment that we’ve been making and every discussion that we have with customers is focused on savings, sustainability, and improving operational excellence and digital transformation,” says Srinivasan. “This is the DNA of our organization, and we focus heavily on this within our own organization as a practice. We practice what we preach, and we’ve also been helping customers on this journey for a number of years.”

Honeywell is committed to helping organizations transform their operations to meet their sustainability goals.

Every investment that we've been making and every discussion that we have with customers is focused on savings, sustainability, and improving operational excellence and digital transformation.

—Ravi Srinivasan, VP GM Industrial Innovation, Honeywell

Honeywell is based in Charlotte, North Carolina, and has over 700 facilities around the world employing over 97,000 people. One of Honeywell’s business units, Honeywell Connected Enterprise (HCE) was founded in order to leverage our domain expertise and help Honeywell transition into a cutting-edge industrial software company. HCE is a leading industrial disruptor, building and connecting software solutions to streamline and centralize the assets, people and processes that help our customers make smarter, more accurate business decisions.

Over the last 20 years, Honeywell has been very focused on decarbonization. “We have the experience of running chemical plants and we are in the process of decarbonization ourselves,” says Deanna Haines, Sr Director Business Dev – Innovation. “We really understand how complex this is and the challenges around it, and we test our own products and decarbonization solutions on our own facilities before we take them out to market.”

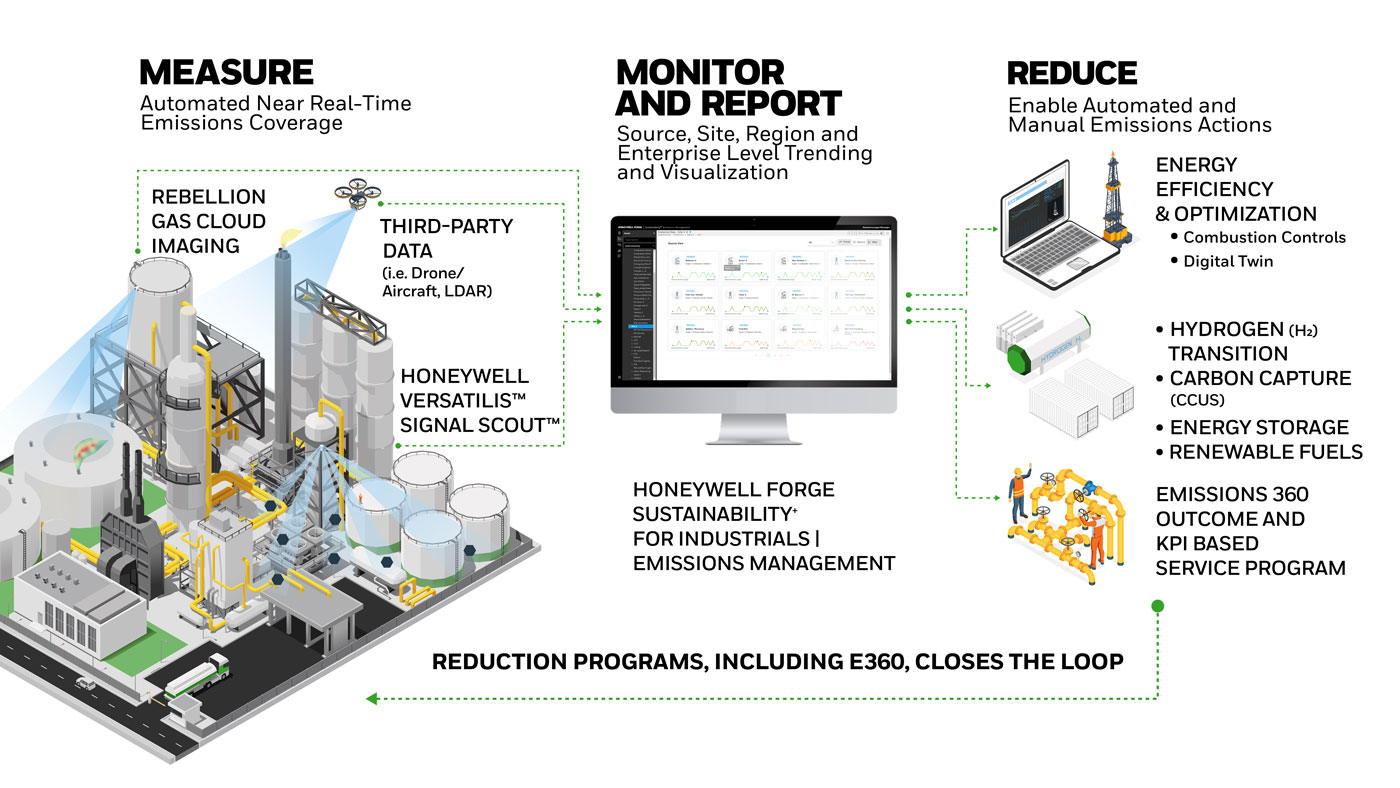

Honeywell’s ambitious goal of breaching net zero by 2035 requires serious investment in understanding the real emission profile of their facilities. “We have the ability to affect the main decarbonization levers for chemical plants and their facilities, helping them establish a baseline of their true emissions, detect losses from their system, and establishing a pathway to reduction,” says Haines. “For example, when our customers become super energy efficient, they save on their utility bills, reduce their emissions while freeing cash-flow to further transformative investments in their business.”

We test our own products and decarbonization solutions on our own facilities before we take them out to market.

—Deanna Haines, Sr Director Business Dev – Innovation, Honeywell

Honeywell has always been a process and control company and describes their approach as “intelligent operations.” Over 50 years ago, Honeywell pioneered the distributed control system (DCS), which revolutionized plantwide operation. Two decades ago, Honeywell introduced the Experion PKS, a process knowledge system, which is the first enterprise-wide solution designed to unify people with process business requirements and asset management.

“Today there are two challenges in the control room,” says Christopher Polaniecki, Sr. Business Dev Manager – HPS PAS. “The first is that operators are being asked to look over more units and be responsible for more programs like operator-driven reliability. The second challenge is the addition of carbon intensity as a KPI. Not only do they have to monitor carbon but also look at ways to decrease it.”

Tathagata Basu, Managing Director, will lead a seminar on “Experion Intelligent Cockpit: The Future of Work in the Control Room.” The Intelligent Cockpit is a combination of four software packages that helps make operators future ready and combines advanced analytics, smart visualization, and artificial intelligence to help operators answer key questions in real time that comes back to the Human Machine Interface (HMI) Pack, the Asset Pack, the Process Pack and the Safety Pack.

Attendees will learn how to utilize cutting-edge tools like sensors and digital twins to gather real-time data and create virtual replicas of physical systems. They’ll learn how to use automation technologies to streamline processes and enhance efficiency. A discussion about integrating AI with human expertise to make operations smarter and more adaptive will follow.

Suhas Hajgude, Technical Consultant, and Dan O’Brian, Technical Consultant, will present “Implementing Sustainability Programs Using Asset Performance Management (APM).”

Asset performance management is not just about predictive maintenance and analytics for equipment. Customers can use insights from their APM solution to optimize overall operational sustainability and meet carbon reduction goals. APM can now monitor and help control energy usage and emissions.

Anil Khatri, Sales Director, Midstream Industry Solutions, Honeywell Process Solutions, will lead another seminar, “Integrated Multi-Modal Terminal Logistics and Operations Execution.” Terminal logistics and operations digitalization is a complex and challenging undertaking, where many companies struggle for success. Honeywell will share its recipe for success, where it took a holistic approach to enabling its customers with an integrated, multi-modal, optimized terminal logistics and operational process and solutions.

Attendees will learn about integrated terminal logistics and operations execution solutions for terminal planning, scheduling and operations for rail tank cars and trucks, and marine operations. In addition, they’ll explore data visualization for enterprise scalability and integration, optimization around financial drivers, and KPI(s) such as cycle time, safety and automation.

Deanna Haines is also a panelist on the kickoff panel on Day 1, “Decarbonization Trends in the Industry.” Her submitted abstract is titled “Navigating the Decarbonization Journey: Honeywell’s Dual Role and Strategies.”

This year attendees will be able to catch the ever-popular Honeywell Road Show Trailer.

Attendees will experience live demos of field instrumentation, process instruments, modular systems, and software. They’ll witness and test pressure, temperature, flow, and level transmitters wired and communicating with the RTU, PLC, and distributor control system. Additionally, they’ll observe liquid analytical instruments, electric actuators, and paperless recorders. Access is provided to an operator console, enabling testing of the software and viewing of operator graphics. A visit to the instrument shop offers hands-on experience with field instruments, accompanied by specialized guidance. The Road Show Trailer will be located in the parking area just outside the exhibit hall.