Busting the canned motor pump myth

Where Precision meets Tradition. A view into Teikoku stator manufacturing (machining bay.)

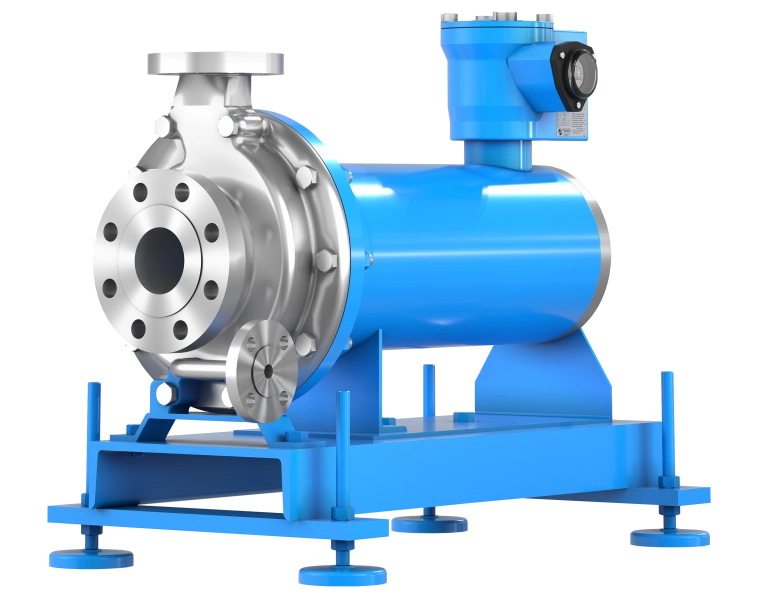

Canned motor pumps are smaller, faster and more effective for critical applications.

“The reason for our existence is to ensure safety through containment and reliability. We achieve this through the canned motor pump,” says Erik Daron, President and General Manager of Teikoku USA Inc. “We find ourselves playing a major part in environmental sustainability by preventing emissions into the atmosphere. With greater reliability from a mechanical simplicity perspective and the ability to work in unique ways, canned motor pumps offer more effective operation compared to other traditional pumping technologies.”

The need for safety, sustainability, and reliability is at an all-time high and still increasing as customers are under deadlines from the EPA for different renewable fuels and methods of energy storage. Users are being driven to improve reliability and reduce downtime. Teikoku answers the need with the canned motor pump, creating more opportunities for customers looking to squeeze greater performance, reliability and efficiency out of their facilities.

Upholding a legacy of unmatched Quality. A view into Teikoku rotor manufacturing (machining bay.)

With US headquarters in Warminster, Pennsylvania, Teikoku is the world’s largest supplier of canned motor pumps. Over the last 50 years, Teikoku has installed more than 700,000 canned motor pumps around the world, covering every possible solution.

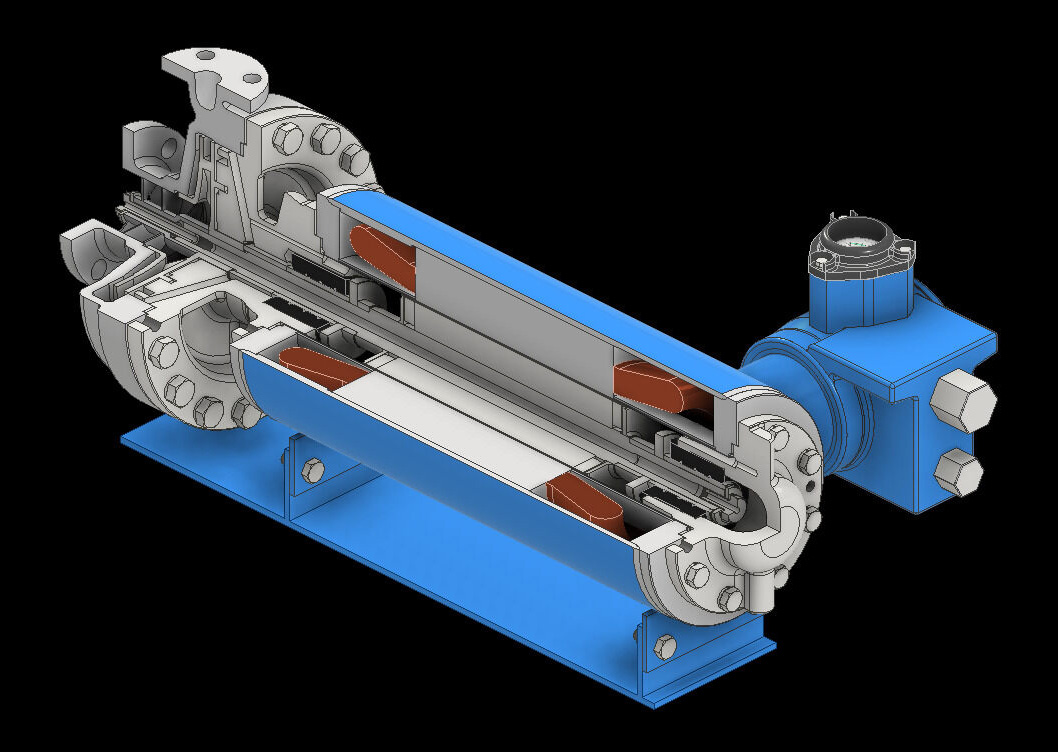

The prevailing theme for the year is the idea that canned motor pumps can achieve higher speeds without compromising reliability or safety. Jim Hoffman, Eastern Regional Business Manager, will talk in more depth about high-speed operation without mechanical sacrifice in a seminar: “Unique Advantages of Canned Motor Pumps from a High-Speed Perspective.” Attendees will learn about the use of fluid-film/process-lubricated bearings and specially wound motors that allow for operation at higher speeds (up to 120 Hz) without compromising equipment lifespan and actually increasing mechanical stability.

Chaitanya “Chatty” Sakhalkar, Director of Sales and Marketing, will lead a seminar entitled “Busting the Myth of Canned Motor Pumps: Installations in Obscure, Difficult and Dangerous Services.” Throughout 2023, the industry evolved from its traditional view of canned motor pumps as being limited to simple or clean applications. Attendees will learn about newer applications that may include high working pressures, high temperatures, fluids containing slurry and/or hydrogen, and fluids with high melting points, as well as volatile and toxic fluids.

Sakhalkar notes that many inquiries for new applications include specifications for lower speeds because many customers have a background of operating pumps with mechanical seals andball bearings. Customers are surprised when Teikoku USA responds with proposals with canned motor pumps that can work at higher speeds. Customers love the idea of a smaller package, and a smaller footprint – typically about one-third the size of a traditional installation.

The prevailing theme for the year is the idea that canned motor pumps can achieve higher speeds without compromising reliability or safety.

—Jim Hoffman, Eastern Regional Business Manager

Drop-in solutions make it easier for a plant to convert from traditional pumps to canned motor pumps, thus upgrading to a higher level of safety and more robust containment. Teikoku USA supports the market with drop-in solutions to embrace these opportunities because now safety is about more than just hot oil. Greater concern for safety also includes areas that have historically had a lower standard from a containment standpoint. It’s now possible to have drop-in solutions with a significantly increased level of safety for high-end highly toxic chemical services.

Teikoku USA also helps customers achieve their sustainability goals in other ways. The ability to go wireless and to store and trend data in real time will empower customers to minimize downtime and use a predictive model to show when maintenance may be required or spare parts needed.

Teikoku USA meticulously manufactures every single component of their pumps in-house to guarantee excellence. The company is also gearing up to expand its manufacturing footprint in the United States to ensure an uninterrupted supply chain for North American customers.

We hear from many customers that have had pumps running for years, since the ʼ90s or even earlier, and they haven’t needed to touch the pumps at all because they’re still working fine.

Jim Hoffman, Eastern Regional Business Manager, Teikoku USA Inc.

Teikoku USA sets itself apart through its outstanding customer service by continuing to support customers long after the initial installation. “We’re very serious about making sure that the user is equipped with an understanding of how the technology actually works, so they can really maximize the benefit that our pumps offer,” says Hoffman. “We make a big investment in training and system overview prior to startup or even prior to an installation. Seeing an installation through from its inception to successful operation not only includes providing a successful product and the necessary knowledge to a user, but also communicating that we’ll be ready to assist them with any issue, whether it’s a simple pump rebuild or a troublesome system that requires us to use data to pinpoint the problem.”

To increase reliability and safety, Teikoku USA provides training free of charge for every new pump that is sent out into the field. Some larger customers like Eastman have training every year for new staff. Customers appreciate this and consider it important for the safety and reliability of their pumps.

Teikoku USA is committed to understanding and meeting the unique requirements of its customers. “We strategically allocate resources across various disciplines to effectively address customer needs,” says Hoffman. “This involves collaboration between highly skilled application engineers backed by a robust design engineering team, all based in the US, interfacing with customers’ own process and design teams to ensure seamless integration in navigating the best technical solutions. Beyond installation, our quality and field service personnel specialize in addressing any routine or unique circumstances throughout the entire lifespan of the service.”

Teikoku USA also offers third-party certification and compliance with third-party industry standards in line with its focus on safety and equipment. After products are sold and installed, Teikoku USA maintains regular communication with the client’s operations, reliability and maintenance teams.

Three customer service centers in the United States are dedicated to keeping customers operational. Teikoku USA does not focus on equipment repair and parts sales as a revenue stream. “We can grow by solving problems that are not related to our pumps,” says Sakhalkar. “Our growth comes from new opportunities in the industries we serve, including replacing bad actors with drop-in solutions.”