Continuing Collaboration

AVEVA and Eastman

are working together

to digitize

While booking a vacation rental though Airbnb or keeping up with friends and family on Facebook, process-industry executives are wondering why technology is changing their personal lives more than their business lives, says Roland Schneefuss, AVEVA Group PLC vice president of sales for North America. That’s why the industry’s interest hasn’t diminished in artificial intelligence, visual intelligence, augmented reality, virtual reality and machine learning since AVEVA addressed a packed house two years ago at eChem Expo, Schneefuss notes. What’s changed dramatically since 2016 is that plant management and operators now expect vendors to deliver more complete solutions, he says.

Two years can bring a lot of change in the world of rapidly evolving technology, so AVEVA is displaying some new product offerings on the exhibit floor this year, Schneefuss continues. “Augmented reality and virtual reality will be added to the booth,” he says. “You will also see early examples of artificial intelligence.” It’s a good idea to define artificial intelligence, or AI, for the sake of discussion, he warns. At its simplest level AI begins when a company uses a database to store and automatically apply the easy rules it has established over the years.

“Where can we take it from here?” Schneefuss asks, referring to AI. A higher form of AI software learns as the plant uses it, he says. The systems pick up the patterns of decision-making that workers establish without articulating them, and then the systems suggest that some designs are better than others and should or shouldn’t be applied together. The process improves predictive maintenance and can factor events into scheduling, he notes.

Two years can bring a lot of change in the world of rapidly evolving of technology, so AVEVA is displaying some new product offerings on the exhibit floor this year.

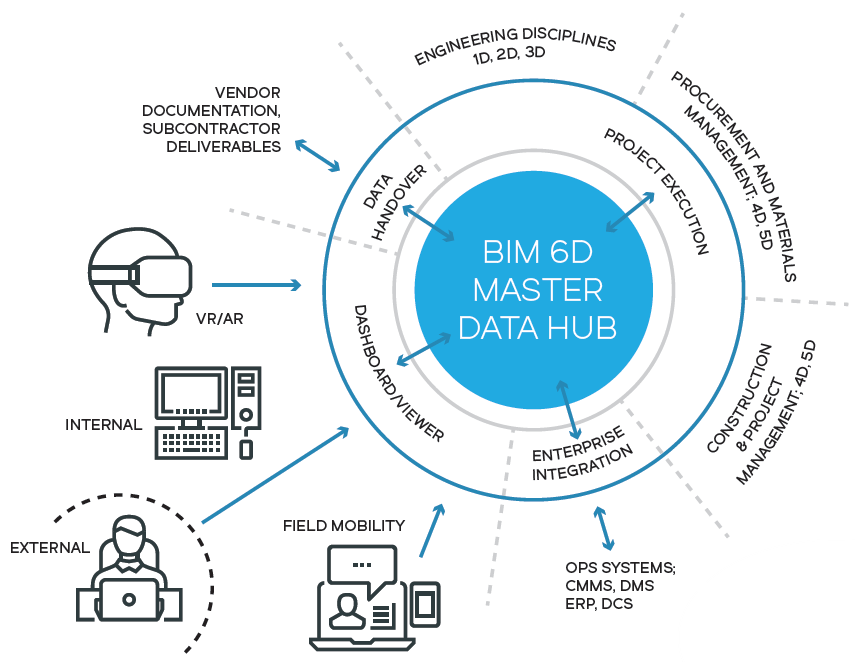

As AVEVA works with Eastman Chemical Co. on a project called SEIGA – an Eastman-coined acronym that stands for Seamless Engineering Information Global Access – the two companies are moving Eastman toward a more-digital future. They describe the process as changing from document-centric practices to data-centric practices.

AVEVA and Eastman are using SEIGA to switch to data from documents partly to pursue the goal of rapid execution, which can be more important than capital effectiveness in the specialty chemical business, according to Quentin Smith, who’s in business development for AVEVA on the U.S. Gulf Coast. “Time to deploy is critical to the ultimate success,” he contends.

Through SEIGA the two companies are engaged in what they call “integrated engineering design,” which brings together all aspects of a project in a data-centric way to accomplish the engineering not only with fewer man-hours – usually 30 percent fewer in the engineering phase – which leads to shorter schedules in executing projects, Smith says.

It’s also easier to make late-stage changes in a data-centric world than in a document-centric world, Smith continues. When a company’s data-centric, all changes are made in a central place. Everyone involved in a design effort can instantly see changes as soon as they’re made, they can see who made the change and then they can collaborate, he notes. “If there’s a shift in a slice of the specialty chemical market that Eastman is looking to exploit, there’s an opportunity to change the project at a late stage without having the schedule cost implications that make that change no longer a valuable business proposition,” he says. SEIGA’s advantages in rapid execution also contribute to capital effectiveness and lower total installed cost, he maintains.

"Artificial intelligence can observe human behavior patterns and suggest improvements."

Roland Schneefuss

AVEVA vice president of sales for North America

A user explores the AVEVA ENGAGE interface

With SEIGA,

waste is reduced and sustainability is increased because SEIGA’s more-efficient projects mean that Eastman buys less material, which lowers shipping costs and cuts waste-disposal costs, Smith says. “You’re ordering the exact amount you need in order to build a project so there’s a sustainability story,” he concludes.

At the same time, the SEIGA addresses mobility because it’s available on mobile platforms, Smith says. That saves time because it eliminates the need for workers to make trips back and forth from the field to a wired source for access to information, he notes. Interviews that eChem Expo conducted with Eastman executives in preparation for the conference and exhibition indicate widespread expectations for dramatically more mobility between now and the next Expo in 2020.

“Safety is another piece we touch” because SEIGA helps participants become more familiar with the project, which heightens safety, Smith notes. Safety isn’t a differentiator these days, he adds, because it’s now considered one of the basics companies must achieve before accomplishing any work.

SEIGA eliminates the need for workers to make trips back and forth from the field to a wired source for access to information.

Cybersecurity has also become a fundamental requirement, and SEIGA helps there, too, according to Smith. “This is a core focus of ours,” he says. “It is something we have right and must continue to have right in order to qualify to do business with a company like Eastman,” he maintains. Schneefuss agrees. “Cybersecurity is something we all care about,” he declares. “Everybody uses more and more data services, whether it is our online bank account or storing our master’s thesis in the cloud,” he says. Protecting data has become as basic as having access to water, electricity and the internet, he maintains.

More of the thinking behind AVEVA’s work with Eastman is expected to emerge during two seminars the companies plan to conduct at eChem Expo. The sessions the two companies conducted at the 2016 Expo drew standing-room-only crowds that included Eastman executives seeking a better understanding of the project, other vendors interested in how learning how they can work with Eastman, EP’s that don’t have big R&D budgets but want to find ways to innovate, and high-level executives from other chemical companies looking for their own way forward, Smith says.

The seminars will address Eastman’s decision to expand its work with AVEVA this year in the SEIGA program. The work up to now has centered on project execution instrumentation and information management, Smith says. It will now expand from instrumentation to include other tools involved in “showcase” projects intended to establish the business case for SEIGA in product execution.

SEIGA was new when the 2016 eChem Expo convened, so seminars on the project at that conference didn’t include many data points, Smith notes. Now, the companies can share numbers that points to successes, he says.

While preparing for eChem Expo, UK-based AVEVA reported having 1,400 employees, a total that increased organically by 300 in the last three years. By the time the conference and exhibition convene, the company expects to finalize its acquisition of Schneider Electric’s software business, increasing its employee roster by 2,600 for a total of 4,000. The combined entity plans to operate under the AVEVA name. Smith describes the hybrid as “pure AVEVA with added capability and a much larger employee base.”